OUR PERFORMANCE: UNMATCHED.

PREMEX IN NUMBERS.

YEAR OF OUR

COMPANY FOUNDATION

trained and

motivated employees

active

customers

modern CNC

machines

Tons of carbide

in stock

TONS OF CARBIDE

PROCESSED / YEAR

active

customers

Tons of carbide

in stock

tons of carbide

processed / year

modern CNC

machines

trained and

motivated employees

YEAR OF OUR

COMPANY FOUNDATION

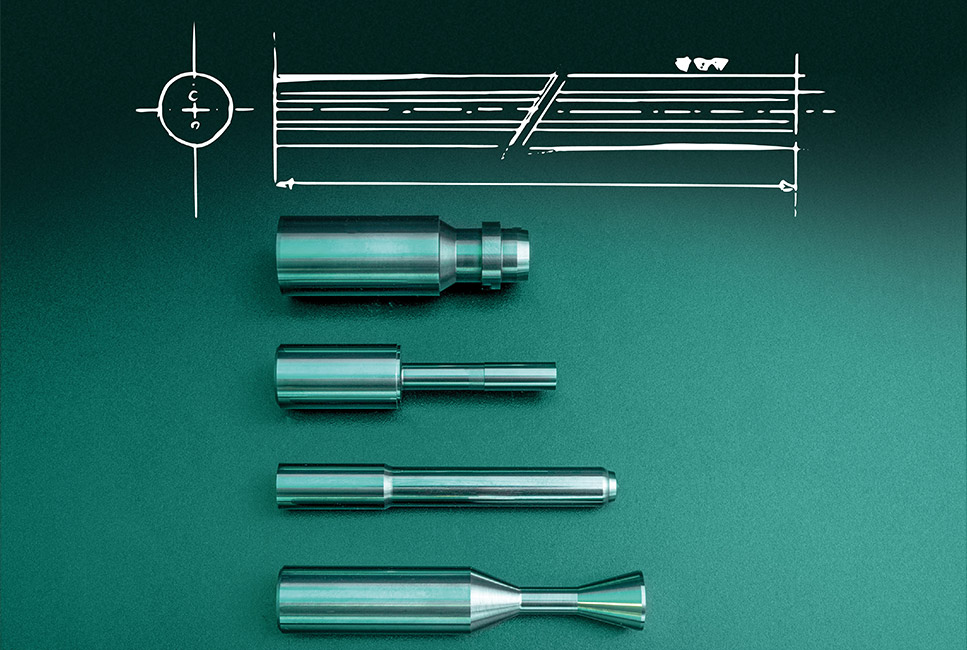

Pre-ground

carbide blanks

As the basis for high-performance cutting tools we grind individual solid carbide blanks according to customer drawings to the highest possible precision. Whether you need a single piece or a whole production series: Quality and on-time-delivery are our top priorities, for which our employees do everything possible every day.

VHM BLANKS AS THE BASIS FOR YOUR TOOLS:

Stock variety

In our warehouse we manage sufficient quantities of all common items from our delivery program. Over the years, we have steadily expanded our product portfolio of carbide variants to meet the ever-increasing variety of products.

YOU CAN RELY ON PREMEX

Quality

management

Over the years, testing and documentation requirements have become increasingly important in the industry. As a result, we are increasingly focusing on this area in order to be able to sustainably deliver the highest quality and transparency in value chain.